Special Engines |

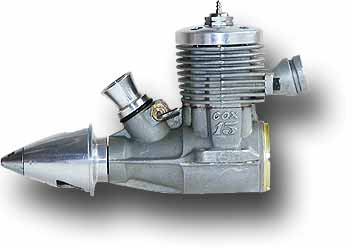

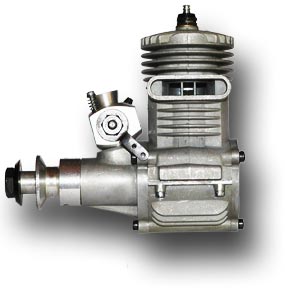

Conquest .15 R/C (2.5 cm³)

Manufactured in 1976-1978 (#2810)

This is a Conquest series engine, with its sleek, cast casing. Like the Tee Dee series, this engine had been developed by Bill Atwood. The stylish, but quite heavy exterior design was done by Philippe deLespinay (better known for his slot car developments and full size racing activities). It was obviously intended to be an intruder into the Rossi dominated .15 market and many parts are even interchangeable. Such a composition was also known as a «Cossi». Some of the development was done by Bruce Tunberg, now working at MECOA. This company, owned by Randy Linsulato, continued to manufacture the Conquest (after being produced by K&B) under its own RJL label (currently out of stock).

[reprint

of test report in PDF format (Aeromodeller April 1976)]

[reprint

of test report in PDF format (Aeromodeller June 1977)]

( manually re-typed facsimile documents with permission of the publishers)

Conquest .15 C/L (2.5 cm³)

Manufactured in 1976-1978 (#2800)

The Conquest .15 free flight and control line engine had a power of about 370 W @ 23'000 rpm (with FAI 80/20 fuel). Timing was different from the R/C version and the manual calls for fuel with up to 70% nitromethane for maximum performance. At $30.00 it was slightly more expensive than the R/C version.

{Thanks go to Jukka Vatanen, Finland, for providing the missing head and exhaust extractor}

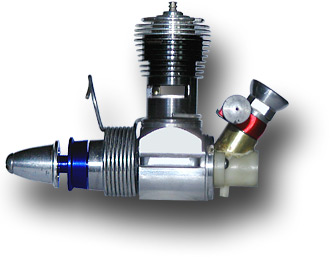

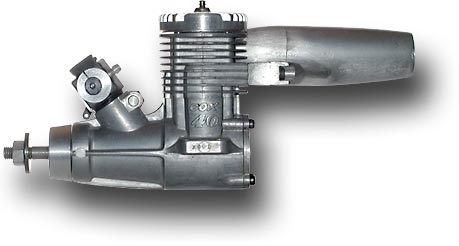

K&B Conquest .15 C/L (2.5 cm³)

Manufactured in ca. 1978

Before ending up at RJL, the Conquest .15 was manufactured and sold by K&B (Leisure Dynamics also owned K&B before John Brodbeck bought the company back). This engine has a copper gasket between cylinder and crankcase and the rear cover is gold anodized . On this sample, a modified glow head insert which carries a Nelson glow plug is used. The crankcase of a K&B produced engine can be recognized because these bear serial numbers.

Olympic .15 Drum Valve (2.5 cm³)

Prototyped in 1965

This is one of the 50 engines built following the design of Bill Atwood. It was the first try to improve the performance of the reed valve engines like Sportsman and Olympic. The basic Olympic was modified with a new crankshaft and a new rear crankcase extension, carrying a white plastic housing with an Olympic venturi. Inside this casing, a rotary drum valve controls induction and tank pressure. Obviously the engines were not fully up to expectations and maybe also too complex and hence expensive to manufacture. The final outcome was the successful Tee Dee series.

{lower engine in collection of Cole Chevalier}

I am still looking for a sample of this engine.

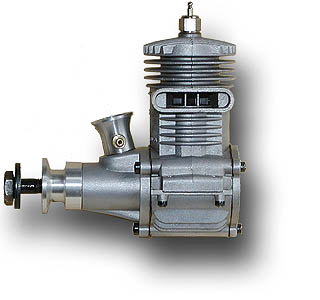

Concept II .35 Sport (6.0 cm³)

Prototyped in 1968 (#2510)

A prototype of the front intake, Schnürle ported .35. These engines never made it into production. Cylinder and head are one single integral part. The crankcase separation is horizontal and plain bearings were used. As a result the engine is very lightweight (218 g).

This engine was also announced with a displacement of .40 cubic inch. I am still looking for a sample of the .40 engine if these exist.

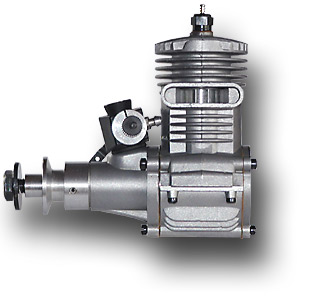

Concept II .35 Front Rotary R/C (6.0 cm³)

Prototyped in 1968 (#2500)

This is the R/C variant of the Sport engine #2510 shown above. The main change besides the Perry carburetor were twin ball bearings, which resulted in a modified crankshaft with closed web, a new prop driver and a modified front crankcase. The samples I have seen were equipped with various carburetors. The weight is 238 g due to the ball bearings.

Concept II .40 Front Rotary R/C (6.5 cm³)

Prototyped in 1968 (#2520)

This is a larger variant of the .35 RC engine #2500 shown above. The main change is an enlarged cylinder bore and a different carburetor. The weight is 238 g due to the ball bearings.

Concept II Rear Rotary .40 R/C (6.5 cm³)

Prototyped in 1968

The drawing shows the engine in a 1969 catalogue, but it never went into production.

The engine was also made with a displacement of .35 cubic inch like the front intake shown above.

I am still looking for a sample of this engine.

{drawing © L.M. Cox Mfg. Co., USA}

Conquest .40 (6.5 cm³)

Prototyped in 1976

Samples and obviously quite a lot of parts have been produced for venturi carburetor as well as a Perry R/C carburetor versions. Basically it is a grown up Conquest .15 with a conventional backplate. During these years, Cox as well as K&B were part of the Leisure Dynamics empire. Because the .40 engine would have interfered with the K&B product line, it never went into production. Only the Conquest .15 was produced under K&B label.

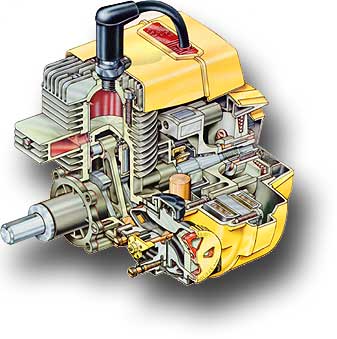

Series 140 - Beaver 1.40 (22.9 cm³)

Manufactured in 1968 (Cox #140-1, ECJ #130a)

You might not believe it, but the Cox did also manufacture a few engines having slightly more displacement than the Tee Dee .010.

Here we have an engine taken from a Cox Beaver chainsaw. This particular engine has been modified by its previous owner to be used in a large model aircraft. While the chainsaw parts like handle and blade have been removed, the basic engine is still in its original condition. All screws except the muffler fastening screws should be slotted screws, though.

The piston is equipped with two rings and runs in a steel liner. The main crankshaft connects to a rear extension, which drives the flywheel and at one time also carried the pull starter. Both shafts are running in needle roller bearings and the engine seems to be a strong, but lightweight design. The spark is provided by the usual high tension coil and magnetos in the flywheel. Induction is controlled by a V-type reed valve, similar in layout to what you find in 2-stroke motorcycle engines.

The exhaust deflector is equipped with an insert, but really cannot be called a muffler.

About 30'000 of these engines, which were also available as a general "utility" engine, were manufactured. This was a relatively small number compared to Cox model engines. One variant of this engine was produced by Cox as a bicycle power unit, called "Bronco". The utility engine was used for example in a portable winch produced by the Warn company of Seattle.

Later Cox sold the manufacturing rights to the Roper company so that these engines exist with "Cox" as well as "Roper" name plates. Finally the last engines of this type were sold by Hobby Lobby under tha name "Rhino 1.4".

The cutaway drawing was lifted from the datasheet, which shows a performance curve peaking over one horse power at 7000 1/min.

I am still looking for better samples of these engines.

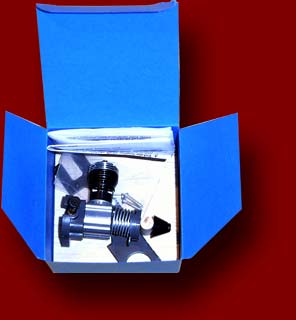

Photograph of the Bronco engine in its sales box.

Product Engine .049 (0.8 cm³)

Small Production Run, 1995-1996

One key to the success of Cox was the ability to streamline the manufacturing process for minimum costs. From time to time new techniques were tried, like the replacement of the machined bar stock crankcase by cast aluminum parts (see R/C Bee). While the basic castings were cheap to manufacture, the drilling and threading operations were more difficult because of the different properties of cast aluminum compared to bar stock material.

Now you might wonder why such a product engine is shown here as a "Prototype". If you look very carefully, you might notice that the crankcase is not shiny, but slightly dull. In fact it is not cast from aluminum, but from a zinc alloy in an attempt to further reduce production costs. Zinc is somewhat softer than aluminum and has a lower melting point. This makes it more easy on the molds, promising a longer life of the tooling. While this proved to be true, this engine did not make it into large scale production (the weight is about the same).

{engine donated by Estes Cox Corporation}

Product Engine .049 (0.8 cm³)

Prototype circa 1990(?)

This is another engine where Cox tried to substitute a different material (zinc alloy) for the crankcase. Another new feature is the boss at the bottom of the crankcase which was intended as a fixture for the starter spring. This design would have made production faster because the end of the starter spring can be more easily snapped over this boss than around the cylinder base. The engine is about 10% heavier than the classical product engine, though and production problems seem to have kept Cox from moving it into mass production.

Electric Fan

Prototype, circa 2002(?)

Estes-Cox developed this electric fan for its RTF (Ready-To-Fly) models. Several Models like the XB-29 Airlifter or the Boomerang were delivered with these fan units installed.

It was planned to package and sell the unit separately, so this package was created. Obviously the market demand was not sufficiently high to justify large scale production, so you won't see this unit at your dealer.

{package donated by Estes Cox Corporation}

Banana Engine .049 (0.8 cm³)

2012

This engine

is assembled by Tissan in Israel from parts which have been supplied by Cox.

The first batch of parts was shipped in 1988 and obviously the stock lasted

at least until 2012. Tissan also sells balsa kits for a small R/C model

("Banana 2000") and a C/L model ("Cricket") for this engine.

This engine

is assembled by Tissan in Israel from parts which have been supplied by Cox.

The first batch of parts was shipped in 1988 and obviously the stock lasted

at least until 2012. Tissan also sells balsa kits for a small R/C model

("Banana 2000") and a C/L model ("Cricket") for this engine.

The engine is similar to the 21916 product engine but has a few differences. Most noticeably, Tissan milled the original double exhaust slits open so that the engines have a wide exhaust slot. The backplate is equipped with a brass fuel nipple and the spinner is a plastic part.

The propeller screw is a Phillips head screw. After Tissan ran out of Cox supplied boxes they produced their own blue cardboard box. There the engine is mounted on a square piece of balsa wood with the help of a wooden dowel.